In Nevada, cannabis wholesalers face a highly regulated environment overseen by the Cannabis Compliance Board (CCB). Compliance spans licensing, inventory management, testing, packaging, labeling, transportation, and meticulous record-keeping. For distributors, the foundation of compliance lies in seed-to-sale tracking through Metrc, Nevada’s mandated inventory platform. Each plant, batch, and finished product must be tagged, transferred with a manifest, and reconciled within the system. Errors such as missing tags, late reconciliations, or incorrect manifests can trigger audits, so wholesalers rely on strict standard operating procedures, role-based permissions, and daily variance checks to ensure data accuracy.

In 2024, Nevada added an approval step for all new items entered into Metrc. Wholesalers must now collaborate with brands earlier in the product development cycle to secure SKU approval, potency ranges, and labeling details. Many have addressed this by creating pre-launch compliance checklists and preparing “shadow” catalog entries to transition products smoothly once approval is granted. These practices help prevent costly delays in distribution.

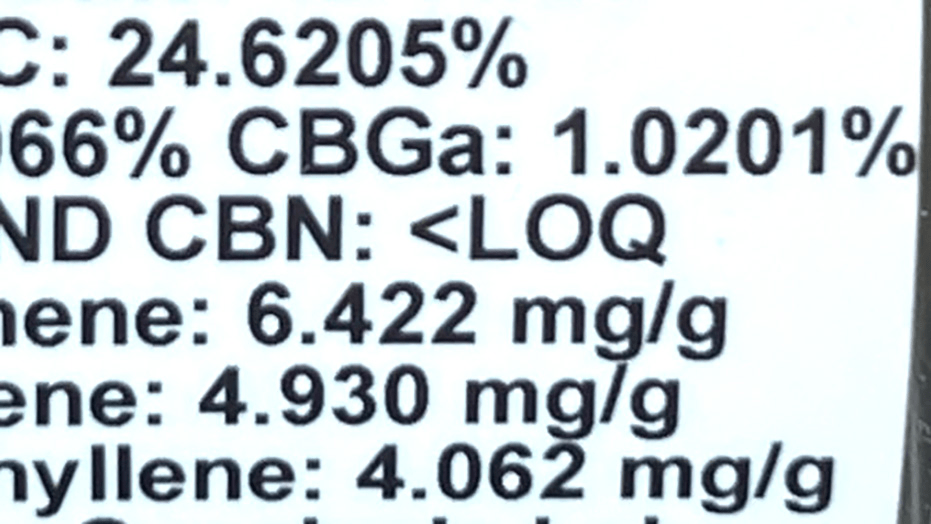

Testing remains another critical compliance area. Nevada requires products to be analyzed by state-licensed labs, which are staffed by scientific directors and subject to rigorous accreditation, inspections, and proficiency testing. Wholesale teams must confirm that certificates of analysis (COAs) match batch identifiers and ensure those COAs accompany products through to retail partners. To minimize the risk of relabeling or product quarantine, many distributors standardize COA formats and implement exception review processes for any batch showing irregularities before it reaches transport.

Packaging and labeling compliance adds further complexity. Nevada enforces strict requirements around serving sizes, THC limits, mandatory warnings, and font sizes. Wholesalers managing multiple brands face added risks if even one product fails to meet specifications. Best practices include pre-receiving packaging and labeling reviews, maintaining master specification libraries by product type, and using automated approval systems to check label artwork against regulatory standards before accepting inventory for distribution.

Public health protections also influence wholesale compliance. Nevada regulators have issued product advisories in the past, such as pesticide concerns, highlighting the need for wholesalers to be recall-ready. Many distributors now maintain lot-level traceability, pre-drafted communication protocols, and retailer notification systems. Some even conduct “recall drills” to ensure their teams can respond quickly and efficiently if an advisory or mandatory recall occurs.

Banking and financial compliance remains a persistent challenge for the industry. While some financial institutions provide limited services, they do so under federal guidance that requires heightened due diligence. Nevada wholesalers often maintain enhanced documentation, transparent cash-handling policies, and transaction monitoring processes to preserve relationships with financial institutions willing to serve the cannabis sector.

Finally, wholesalers must remain agile in adapting to statutory updates. Shifting regulations around consumption lounges, transport rules, and product categories require constant monitoring. The most prepared operators designate compliance officers to track regulatory changes, subscribe to CCB updates, and schedule quarterly policy reviews to keep staff training and operational manuals current.

For cannabis wholesalers in Nevada, compliance is not a static requirement but an ongoing discipline. By building strong systems, investing in training, and embracing proactive strategies, wholesalers can meet the state’s rigorous standards while maintaining efficient and reliable operations.